REDHy project

About REDHy

The REDHy method is uniting academic and industrial entities across a broad spectrum of expertise. Unlike SoA electrolysers, REDHy is entirely free of critical raw materials and doesn’t require fluorinated membranes or ionomers, while maintaining the potential to fulfil a substantial portion of the 2024 KPIs. In accordance with Europe’s circular-economy action plan, a 5-cellstack with an active surface area exceeding 100 cm2 and a nominal power of 1.5 kW will be developed, capable of managing a vast dynamic range of operational capacities with economically viable and stable stack components. These endeavours will guarantee lasting and efficient performance at elevated current densities (1.5 A cm-2 at Ecell 1.8 V/cell) at low temperatures (60 °C) and suitable hydrogen output pressures (15 bar). The project will produce and validate a prototype in a laboratory setting for 1200 hours at a maximum degradation of 0.1%/1000 hours and achieve TRL4 (technology validated in the lab).

Objectives

Develop highly efficient and durable materials free of critical raw and fluorine free materials for the REDHy technology.

Validate the stack’s efficiency and robustness to address dynamic situations frequently occurring when the electrical grid is fed by a large proportion of renewable energy sources or if the system is directly interfaced with RES.

Eliminate the use of and the need for critical raw materials and fluorinated membranes and ionomers at stack level.

Demonstrate optimization strategies for the porous electrodes to enhance their mass transport characteristics and enhance energy efficiency.

Demonstrate a reduced energy consumption of at least 48 kWh kg-1 H2 by implementing highly reversible, stable redox mediators with enhanced kinetics.

Demonstrate a drastic reduction in interface resistances across all cell components leading to energy efficiencies >82%.

Demonstrate the decoupling of oxygen and hydrogen production and enabling the REDHy system to operate at minimum 5% of partial load operation (nominal load 1.5 A/cm2) without exceeding 0.4 % of H2 concentration in O2.

Demonstrate that the REDHy technology is capable to perform efficient and direct seawater electrolysis.

Integrate the short stack in a prototype full system.

Demonstrate the operation of the REDHy electrolyzer at 1.5Acm-2 with electricity consumption of 48 kWhkg-1 over at least 1200 hours of operation with a degradation of 0.1 % /1000 hours.

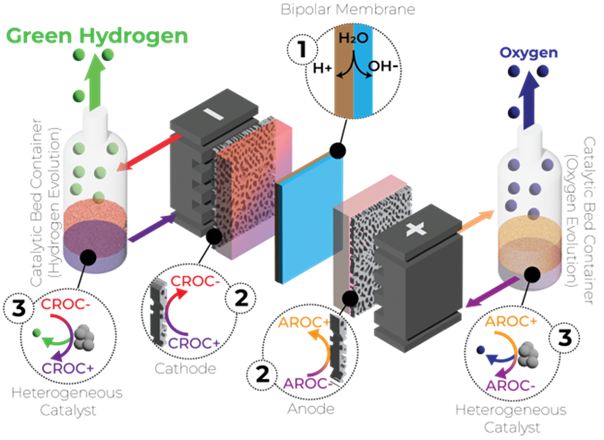

Concept

The principle of the REDHy technology is presented in the figure, representing the explosion view of the electrochemical cell and the external catalytic bed reactors decoupling the green hydrogen and oxygen production: 1) Applied potential initiates water dissociation into protons and hydroxide ions traveling to the opposite charged electrodes, 2) at the electrodes cathodic redox couples (CROC) and the anodic redox couple (AROC) are fed and charged by the applied potential, 3) Charged CROC and AROC are transferred to the catalytic bed container reducing the protons to hydrogen and oxidizing the hydroxide to oxygen in contact with the heterogenous catalysts in the catalytic bed.

Approach

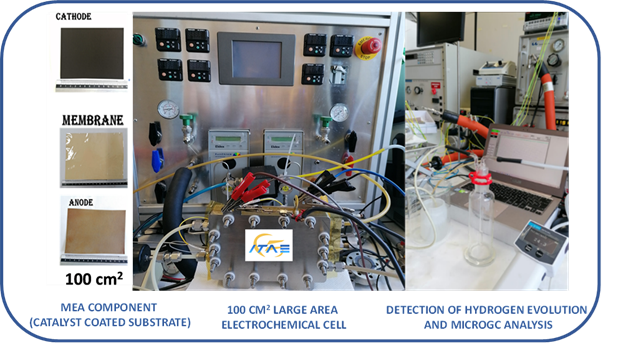

The developed redox mediators, materials and functional components will be assessed in a prototype consisting of a single cell and external catalytic reactors. This first base-prototype will be produced by extending the single cell electrolysis test rig allowing to make a screening of the components under practical operating conditions and to assess the achievement of relevant project targets at single cell level (TRL3). As presented in the figure below

Structure

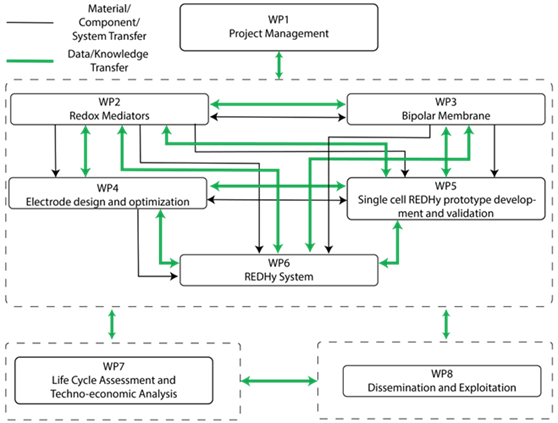

The REDHy project consortium consists of 7 organisations from which all are work package leaders. The project

work plan duration spans over 48 month with 8 work packages and 28 deliverables and 19 milestones. The graphical representation of the project schedule including the timing of the tasks, deliverables and milestones is represented below.

Results

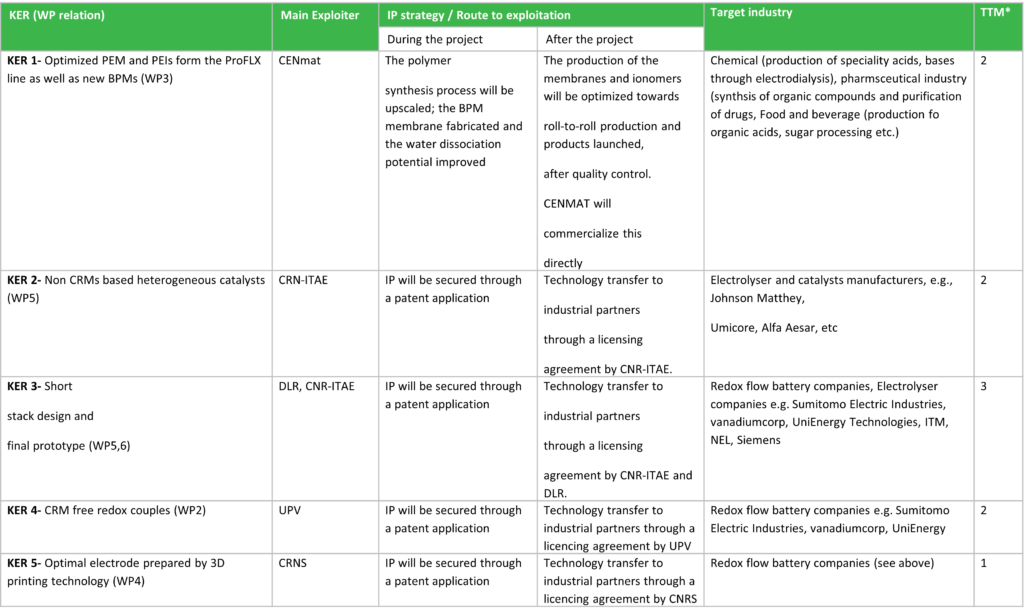

A preliminary list of expected results, potential end users, IP protection, and routes to exploitation of REDHy is presented below:

Facts and figures

Acronym: REDHY

Title: Redox-mediated economic, critical raw material free, low capex and highly efficient green hydrogen production technology.

Duration: 48 months

Start date: 1-1-2024

Total budget: €2,990,238.75

EC Funding: €2,990,238.75